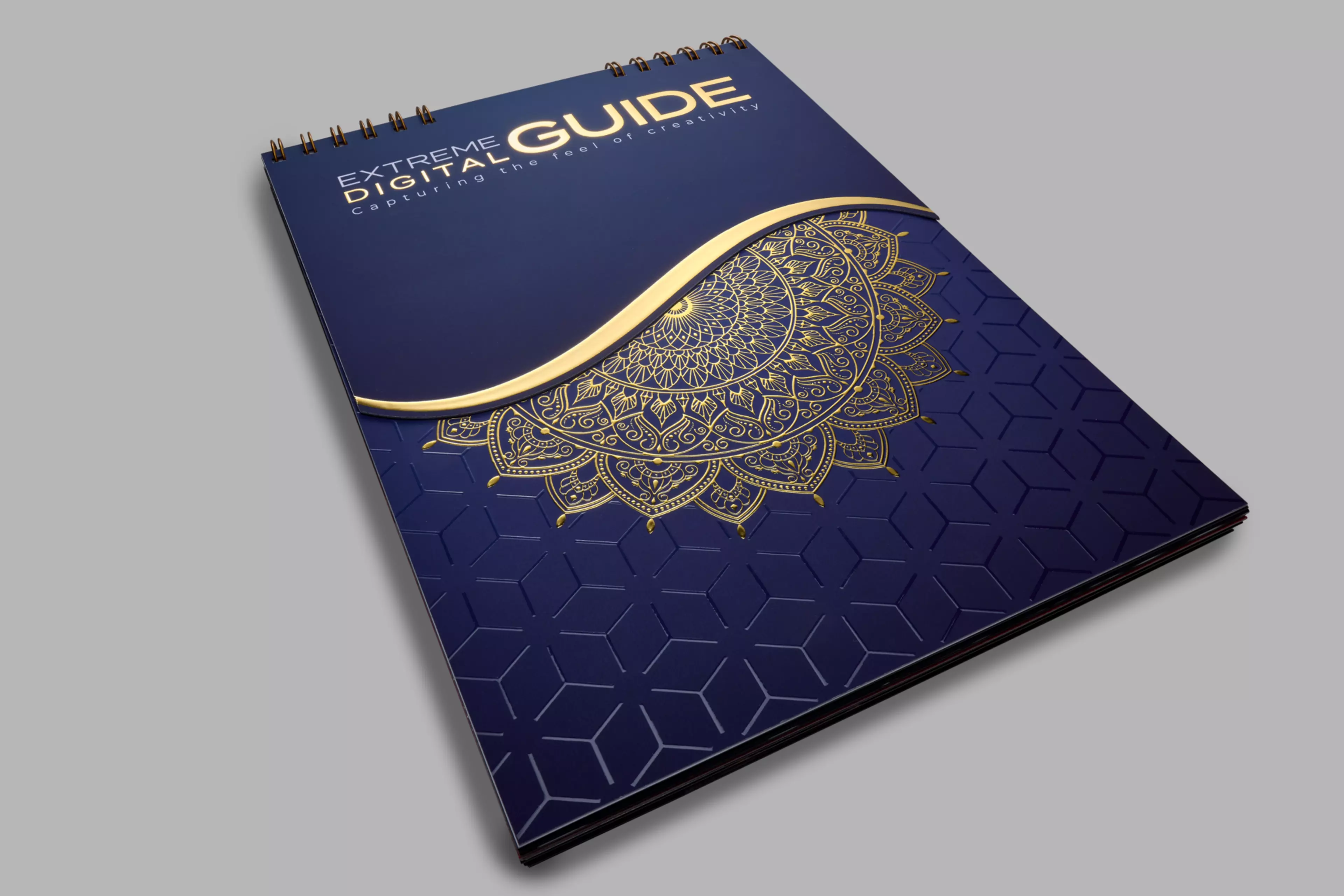

In a recent webinar NAPCO reported the global market in embellishments is growing at 6% to 8% annually. It projected the specialty print market will grow to $45bn by 2028.

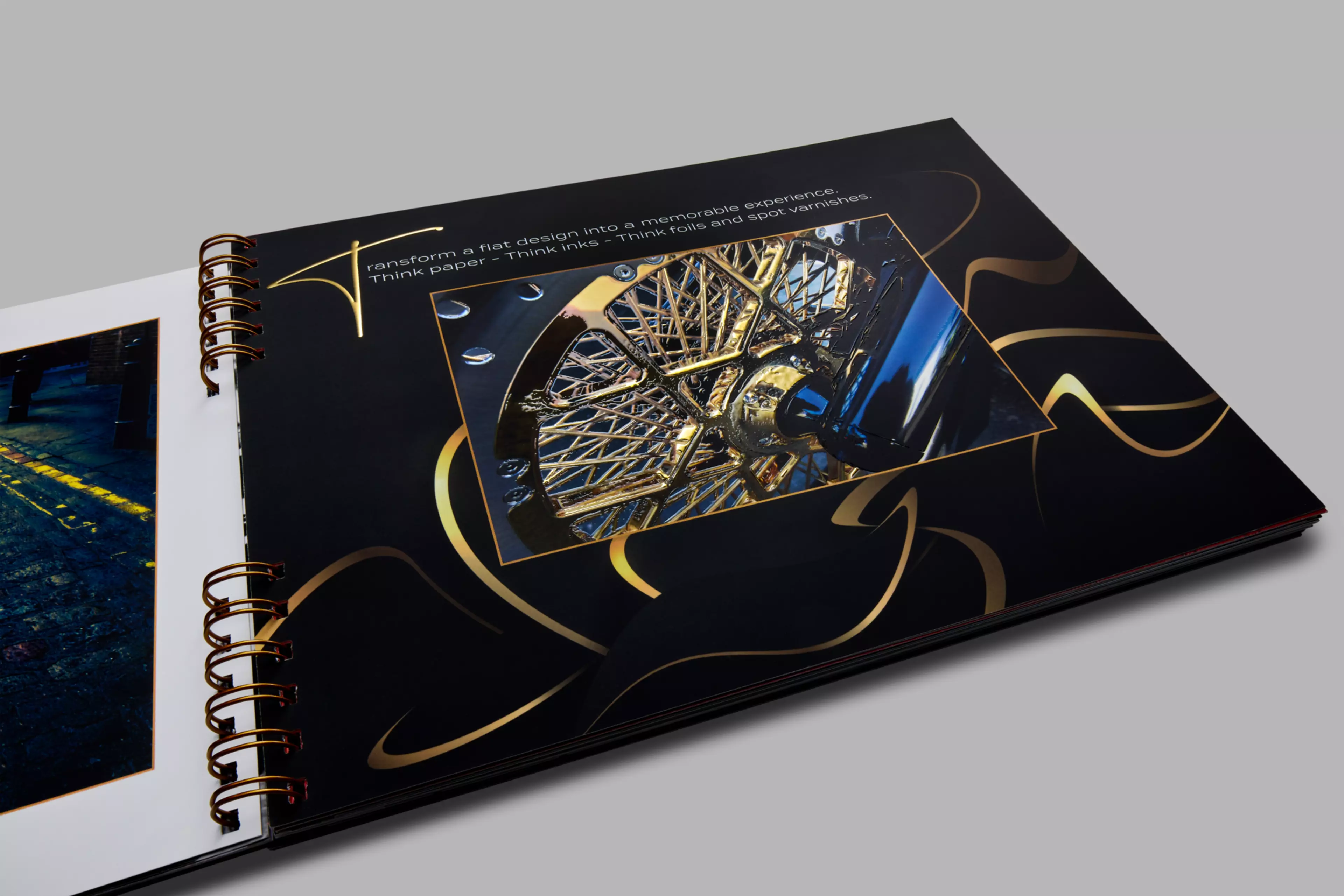

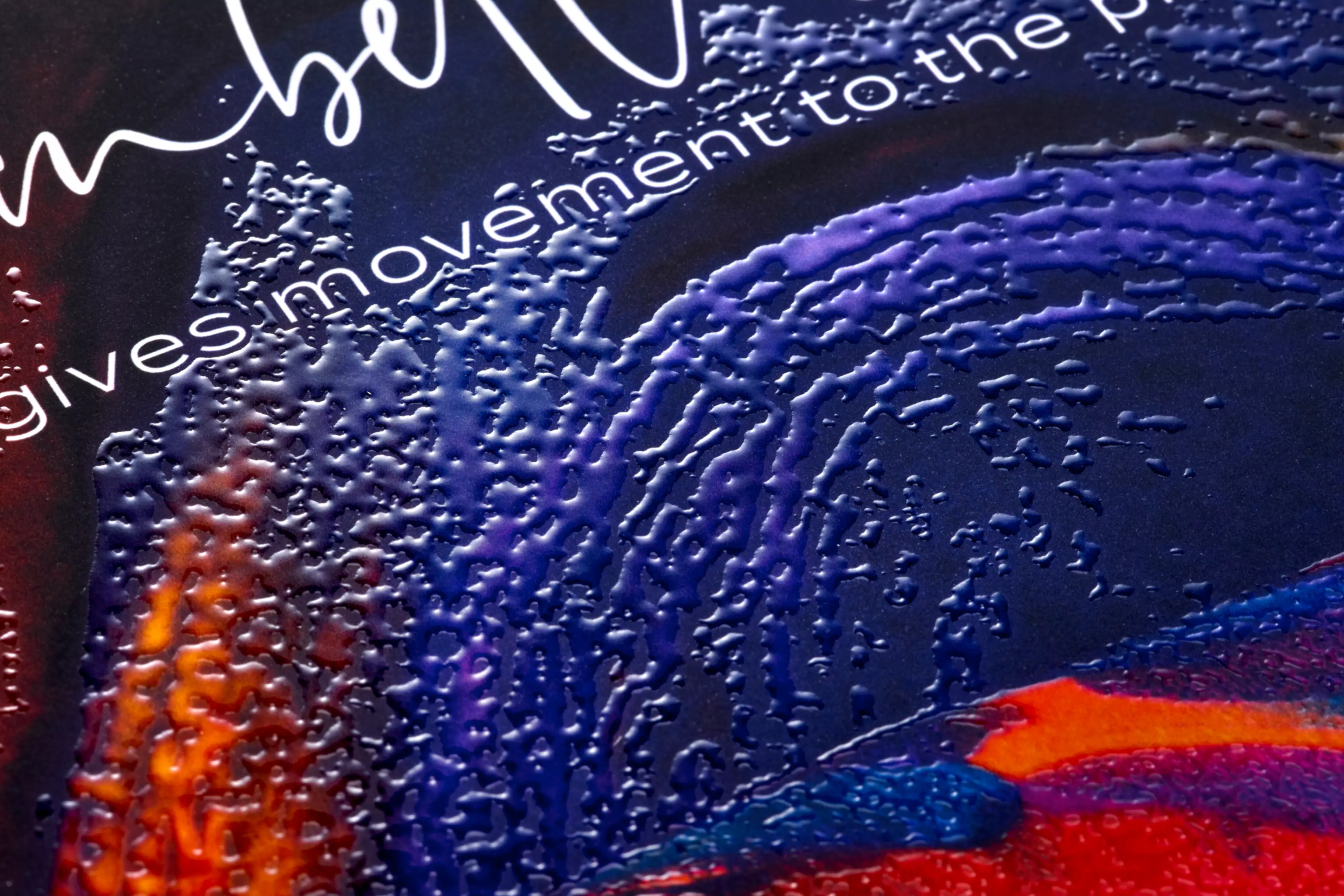

But the impact on the bottomline is more tangible. Keypoint Intelligence found creating a superior, value added experience with digital embellishment enables print service providers to generate healthier margins – especially with print buyers willing to pay premiums ranging from 24% to 89% for special effects over standard CMYK only printing.

This presents exciting opportunities but for those who are unsure about exploring the potential of this market here are three reasons to embrace it: