Manufacturers of apparel, fashion and décor fabrics faced with ballooning energy consumption and water charges are helping to drive increased demand for digital textile printing. It has an evolving pattern. Textile print is an industry that has evolved significantly over the years. And the design means there is significantly less waste because ink droplets are produced on demand in the fabric. Some experts estimate that digital fabric printing can lower energy use by as much as 30% and water use by up to 90%.

Minimal downtime, advanced automation and missing nozzle detection / compensation – two of the many benefits of textile printing with our high-end systems.

This growing market is based on direct-to-garment and direct-to-fabric printing processes, with applications across industrial textile, décor, clothing and apparel. With no limit on design opportunities, digital print comes into its own. It's in fashion and has many benefits over other traditional technologies such as screen printing.

Fast fashion (SPA – Speciality retailer of Private label Apparel) is also on the rise, thanks to digital printing being increasingly used to answer the demands for ever-shorter order delivery times for fabrics. With digital, it means a designer can make last-minute changes whatever the fabric used or pattern required.

Key design features include market-leading reliability and colour yield, as well as high safety and environmental standards that drastically reduce environmental impacts of traditional textile printers. In addition, Konica Minolta’s REACTIVE dye meets GOTS (Global Organic Textile Standard) certification requirements.

Textile print is in fashion and is becoming more popular across the board. Whether it's cotton, cloth, paper or even general homeware products there are so many different patterns to choose from.

Textile printers looking for the best technologies for their business are in the right place. Our textile print systems are designed to allow customers to achieve unprecedented precision, high speeds to increase productivity, improved stability to minimize machine downtime, all while guaranteeing ease of use and maximum reliability and safety for the printed product.

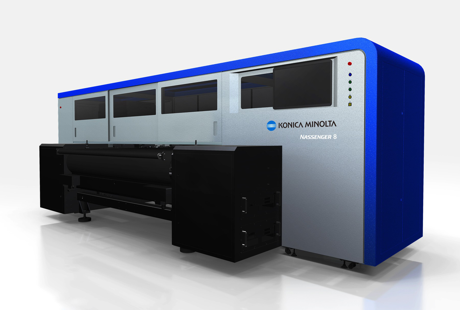

Konica Minolta first introduced its new inkjet printing digital textile machines at the ITMA exhibition in 2015. Two are scan-type high- and medium-speed textile systems, NASSENGER 10 NASSENGER 8. They meet a variety of medium-volume printing needs ranging from sample printing to low-volume printing. Both systems have various printing modes ranging from high productivity to high image quality through to high density / high colour penetration mode. They are equipped with inkjet printheads that are also used in Konica Minolta’s flagship inkjet textile single-pass digital printer, the NASSENGER SP-1.

Konica Minolta remains firmly committed to innovations in the manufacturing process in the textile market by offering higher-performance, environmentally friendly products, and to helping customers enhance their corporate value, while joining the global effort to reduce environmental threats.

The NASSENGER models were launched in response to the increasing use of digital on-demand printing for textiles where reducing downtime between jobs is critical. Another factor was greater environmental awareness to reduce effluent and the use of fuels.