Digital technology – a licence to print labels?

Digital label production is booming. To take advantage of that growth, enjoy digital's new benefits and keep your analogue production equipment profitable while transitioning with Konica Minolta's complementary approach to printing services.

Professionally printed labels are big business nowadays. Very big. Industries need to identify and differentiate their products and brands, custom labels can be used in exciting new ways, and the volume of printed square metres in the sector has nearly doubled in recent years. Even in this online era, label design plays a hugely important part in acceptance of a product. The label or sticker on a bottle or item of packaging reflects its brand's message and identity.

The latest figures from the marketing research institute Smithers Pira show that the volume of printed square metres in this sector rose from 4 billion in 2014 to 7 billion in 2017.

What is label printing?

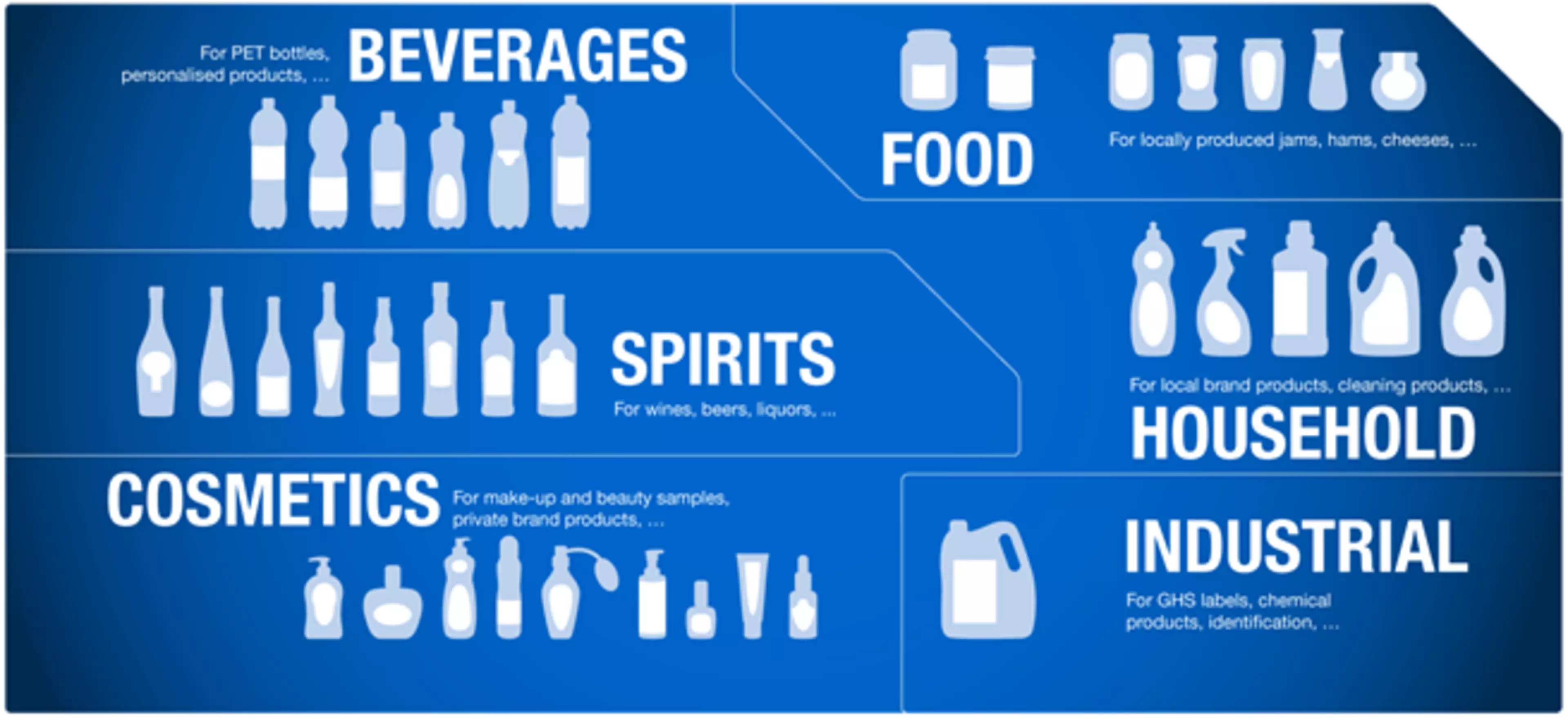

It would be impossible today for the worlds of retail, commerce, industry or distribution to operate without labels. They can be found with multi-coloured illustrations on almost everything that we buy in high street retail stores, pharmacies, DIY shops, and even out-of-town hypermarkets and garden centres – whether products are pre-packed in bottles, tubs, jars, pots, trays or other types of containers, shrink-wrapped or even affixed directly to items as diverse as lawnmowers, tennis rackets, clothing or hardware.

Labels are an essential medium that can be used to identify and help to market all kinds of goods, as well as provide essential consumer or legislative information such as weight or volume, supplier or manufacturer contact details, ingredients or contents lists and maybe storage, handling, healthy eating, usage or safety information.

In addition to this, almost all labels nowadays carry a barcode – the patterns of black and white lines that are scanned at automated checkouts – to identify and price items on the customer's till slip. Barcoded labels of various kinds are also used in the manufacturing, handling, shipping and distribution sectors for applications as diverse as assembly and factory automation, in parts and components identification, and the field of tracking and traceability throughout the supply chain.

New label innovations in recent years have also seen the growth of special types of labels capable of interacting with mobile phones to access websites, provide further consumer information, enter competitions, play games or become part of social networks. Some labels are even uniquely variable or personalised.

In short, labels have become an essential component of everyday modern life in one form or another. No surprise then, that labels of all kinds are one of the fastest growing sectors in the printing industry, along with flexible packaging, averaging around 4-6% per annum growth worldwide for at least the last 30 years (current growth is estimated at 4.7%), and almost always achieving growth above GDP. On a global basis, labels are produced by a highly specialised niche printing industry sector which currently generates over $60 billion in turnover.

Download this whitepaper for free:

The benefits of label printing

Digital label presses

The label printing sector has grown to such an extent that annual installations of digital label presses are now close to 30% of all narrow-web press installations worldwide, with over 3,000 digital label presses installed worldwide in the label industry at the end of 2015.

Looking ahead, digital label presses are forecast to make-up close to 40% or more of all annual narrow-web press installations by 2020.

Against this backdrop, the overall value of digitally printed label jobs nowadays is viewed as far greater than the printed cost alone. Industry estimates indicate that although digital label printing is currently only about 3% to 5% of all printed pressure-sensitive label jobs by volume, it makes up some 15% to 18% or more of all print jobs by value.

The many benefits of this growing sector include:

Seamless workflow

A seamless workflow has become one of the essentials of successful digital label production. It provides the basis for minimizing errors and paperwork, speeds up response times, and provides continually up-dated manufacturing and customer information, as well as bringing down lead times.

Cost efficiencies

Compared to conventional label printing, the digital process does not use printing plates, or have any platemaking materials, chemicals, processes or time requirement, saving you money.

Production benefits

For the brand owner, the opportunity to reduce or eliminate label warehousing, reduce time to market, and improve supply chain efficiencies can be a compelling reason to turn to digital label production. The possibility of just-in-time production, short-run proofing and test marketing of labels is also of great interest.

Marketing opportunities

New added value and marketing opportunities for brand owners – indeed almost any size business ‒ have become a real focus for label users in today's ever-competitive environment. There are many examples of where digital printing solutions have provided the possibility to easily produce multiple versions or variations, variable design images, personalized labels, mass customization, new promotional opportunities and even regional, seasonal or special event labels. For the digital label producer these marketing opportunities offer the potential to add value and enhance profitability.

Environment and sustainability

There is little doubt that the environment and sustainability have become important issues. By producing exact quantities rather than a percentage of 'overs', digital printing reduces print wastage. Unlike other printing processes, there are also no chemicals, water, or plate making materials used with digital printing.

Brand security

A relatively new, but growing area for digital design and printing with the latest software solutions is to incorporate security design backgrounds and special features, variable images, micro text, anti-copy features and much more.

Track and trace

The fact that digital labels can be printed individually means printers can produce sequentially numbered or coded labels, create hidden codes matched to visible codes, and provide changing codes that can be used with smartphone technology – all offering new possibilities for track and trace label solutions.

Digital label presses

The label printing sector has grown to such an extent that annual installations of digital label presses are now close to 30% of all narrow-web press installations worldwide, with over 3,000 digital label presses installed worldwide in the label industry at the end of 2015.

Looking ahead, digital label presses are forecast to make-up close to 40% or more of all annual narrow-web press installations by 2020.

Against this backdrop, the overall value of digitally printed label jobs nowadays is viewed as far greater than the printed cost alone. Industry estimates indicate that although digital label printing is currently only about 3% to 5% of all printed pressure-sensitive label jobs by volume, it makes up some 15% to 18% or more of all print jobs by value.

The many benefits of this growing sector include:

Seamless workflow

A seamless workflow has become one of the essentials of successful digital label production. It provides the basis for minimizing errors and paperwork, speeds up response times, and provides continually up-dated manufacturing and customer information, as well as bringing down lead times.

Cost efficiencies

Compared to conventional label printing, the digital process does not use printing plates, or have any platemaking materials, chemicals, processes or time requirement, saving you money.

Production benefits

For the brand owner, the opportunity to reduce or eliminate label warehousing, reduce time to market, and improve supply chain efficiencies can be a compelling reason to turn to digital label production. The possibility of just-in-time production, short-run proofing and test marketing of labels is also of great interest.

Marketing opportunities

New added value and marketing opportunities for brand owners – indeed almost any size business ‒ have become a real focus for label users in today's ever-competitive environment. There are many examples of where digital printing solutions have provided the possibility to easily produce multiple versions or variations, variable design images, personalized labels, mass customization, new promotional opportunities and even regional, seasonal or special event labels. For the digital label producer these marketing opportunities offer the potential to add value and enhance profitability.

Environment and sustainability

There is little doubt that the environment and sustainability have become important issues. By producing exact quantities rather than a percentage of 'overs', digital printing reduces print wastage. Unlike other printing processes, there are also no chemicals, water, or plate making materials used with digital printing.

Brand security

A relatively new, but growing area for digital design and printing with the latest software solutions is to incorporate security design backgrounds and special features, variable images, micro text, anti-copy features and much more.

Track and trace

The fact that digital labels can be printed individually means printers can produce sequentially numbered or coded labels, create hidden codes matched to visible codes, and provide changing codes that can be used with smartphone technology – all offering new possibilities for track and trace label solutions.

Why digital label printing creates new business

New opportunities

Digital label printing also brings in more business for the converter's conventional printing presses, while creating new opportunities in the shorter run and niche unsupported film markets for sleeves and flexibles. Around 14% of label converters that have invested in digital presses now also produce profitable shorter-run, mid- to narrow-web flexible packaging – sachets, pouches, tubes, pot lids, wrappers, bags and flexibles – for customers who started out on labels alone.

New opportunities

Digital label printing also brings in more business for the converter's conventional printing presses, while creating new opportunities in the shorter run and niche unsupported film markets for sleeves and flexibles. Around 14% of label converters that have invested in digital presses now also produce profitable shorter-run, mid- to narrow-web flexible packaging – sachets, pouches, tubes, pot lids, wrappers, bags and flexibles – for customers who started out on labels alone.

Label Printing

Technology of the future meets benefits of the present

Konica Minolta offers an easy-to-use suite of quality software and hardware that lets you enjoy all the benefits of new digital technology with none of the potentially negative effects of transition.

It's designed to give you the technology of the future – without having to sacrifice the benefits of the present.

All the features you need (and one or two more)

Konica Minolta's powerful mix of software and hardware solutions has been created with one objective in mind: to enable your company to move seamlessly from analogue to digital processing, lock your printing business solidly into the booming profits of the label design of the future, and enjoy the maximum benefit and added value of digital.

Our features will let you offer your clients personalisation, lower your running costs, simplify your operation and put together your own seamless, customised version of the transition to digital. You can offer shorter run-lengths, flexible delivery times and much more. At the same time, those trusted analogue presses will just keep on running with our product mix. In short, our features let you enjoy all the benefits of the new technology while keeping your existing analogue plant profitable as you transition. So what are those features? The benefits to your company of our digital label printing product mix include:

Do I need to change to digital? Find out with Digital1234

For conventional analogue label converters looking to invest for the first time in digital label printing, there is more behind the decision than simply buying a new printing press or process. It requires a great deal of evaluation and thought beforehand, including decisions about people, sales and marketing, pre-press capabilities and colour management at each individual company.

Identify, Assess, Justify and Implement

Investing in digital label printing means stepping back and taking a critical look at the way you do business and how you liaise throughout your work chain and with your customers. For busy label printers and converters looking to invest in digital printing technologies for the first time, the challenge is often to know what questions to ask themselves, who in the company should be involved in the decision-making process, and what the implications for other departments, or even customers, might be.

To assist companies in their thinking and decision-making, Konica Minolta has designed the Digital1234 assessment guide. This business development programme is a business-based questionnaire covering a range of crucial business topics; using a simple and visual 'traffic light' system, the assessment helps you quickly identify the areas of your business that could benefit from switching to digital by exploring each individual business opportunity. It focuses on the specific needs of label converters and companies involved in the graphic arts fields.

By examining area such as your existing business, how you might generate new business by investing in digital, your employees' understanding of digital printing, and management of the digital production environment, the Digital1234 four-step plan – Identify, Assess, Justify and Implement – will tell you for sure whether the time is right for your organisation to switch to digital.

Those four steps are:

Get fit for tomorrow's markets – today

Contact us

The benefits of label printing include seamless workflow, cost-efficiency, production, marketing opportunities, environmental sustainability and many more.

If you would like to chat to one of our experts about the benefits of using Konica Minolta to put together the best digital label printing solutions in the industry today, or test-drive our latest products to find out which would be right for your company, just click below to Contact Us!

Revolutionizes production for GrafiPrint

AccurioLabel 190

GrafiPrint prides itself on a customer-focused approach and understanding their demanding requirements, which is exactly the kind or relationship it seeks with its suppliers. That is how the Italian printer, which produces labels for the local food industry digitally, works with Konica Minolta and its local dealer Sicilia Ufficio and why it chose to enhance its label production with an investment in an AccurioLabel 190.

Improvements and benefits

The adoption of new technology has enabled the operation to embrace new trends, grow its capabilities and enhance its profitability. The AccurioLabel190 can also easily print samples which is a big advantage when engaging with new clients.

Crucial to the success has been Konica Minolta’s fast and responsive support and good working relationship with its local dealer delivering a 360-degree consultative and service approach. A central figure in the pre- and after-sales consultancy has been Fabio Sauro, of local dealership Sicilia Ufficio, who spent considerable time understanding all requirements, particularly the technical specifications and providing ideas on how to grow revenue for GrafiPrint following the investment.

Applying the global expertise and philosophy of Konica Minolta to local requirements, it is, as he says, a “perfect marriage”. In a consultative approach, this has enabled the team to explore the possibilities and expand GrafiPrint’s production capabilities.

Sicilian winery Cantine Fina is among many, satisfied customers of GrafiPrint who recognise the huge value of a quality label that can amplify sensory experiences and is often the starting point of a conversation while relaxing with a bottle of wine. “GrafiPrint’s expertise and the technology it uses helps us to continuously improve our business. We value the close relationship with GrafiPrint, a company in total control of everything in connection with the printing of labels. This is extremely important, because the first bottle is sold by the label, the second by the producers”, says Marketing Manager Federica Fina.

Customer presentation

Family-run business GrafiPrint was established by Fabio Piacentino as a digital printing centre, with its own graphic studio, in just 40 sqm in 2006. Today the successful operation has expanded six-fold and supports companies in the wine and food sectors. Fabio Piacentino’s belief is that labels create emotions and can amplify people’s sensory experiences. This philosophy is extremely important for the food sector where quality and trust are essential values. Hence, the label become a means of communication so deserves a high level of care and attention in the detail.

Key drivers for investment

GrafiPrint wanted to build further on its reputation as a high quality label producer by elevating its capabilities to better reflect its passion for print. It also wanted to be more responsive to an increasing number of short-run orders and meet customer requirements for stockless inventory. It sought comprehensive expertise, fast support and a framework to develop ideas to grow revenues.

GrafiPrint had invested in a small entry level roll-label printer, but quickly realised it needed the ability to print at a higher quality on a varied substrate range, with a broader colour gamut and providing impactful finishing capabilities.

Konica Minolta solution

First seen at Labelexpo in 2017, the AccurioLabel190 toner system quickly matched the company’s exacting requirements. It has improved business massively. The team liked its high quality and productivity, especially for small runs. That meant it could easily elevate its production capabilities and enable customers to broaden their label printing opportunities, particularly with fast-turnaround and personalisation requirements. The Konica Minolta AccurioLabel190 targets label converters of all sizes and is affordable as an entry-level machine for digital printing and can seamlessly complement and work side by side with systems already in place. It also assures outstanding quality, ease of use, and is highly compatible with many post production finishing solutions. The system was a perfect fit for GrafiPrint.

Investing for growth and profitability - The role of digital printing in the world of labels

The rapid acceptance and investment in digital printing had a major impact on the rapid growth of label printing, changing the way custom labels are designed and manufactured and how they can be used in exciting new ways, for example wine labels, food labels and water bottle labels.

Hybrid functionality for AccurioLabel with new Flexo Printing Unit

Extend the range of print applications on your AccurioLabel press by adding the Flexo Printing Unit that let’s you pre-print white (or any other flexo ink) which can be overprinted with CMYK in one single pass, using our overprint sensor kit. This module is a retrofittable option for AccurioLabel 190 and AccurioLabel 230, developed for Konica Minolta by Grafisk Maskinfabrik A/S in Denmark.

How we help Firus Druck to impress their customers

Firus Druck, a traditional label printer from a renown German wine region (Mosel), was looking for the right solution for their customers demand of self-adhesive wine labels. They invested in a Konica Minolta AccurioLabel 190 and a GM DC330Mini as well as a GM HOTFB330 Standalone Hot Foil.The video describes how the investment is part of a wider strategy for our customers’ growth and development. It is about embracing new technologies and change within the ever-changing printing market.

Colours are processed at a resolution of 1,200 dpi x 8 bit with 256 gradations expressed in 1 pixel

Image density control technology

No pre-coating of media required

Operation is intuitive by following on-screen instructions; no need for extensive user training

Per-minute speeds of 23.4 m, 18.9 m, 13.5 m and 9.45 m can be selected to match the media used

Simitri® HD E toner technology

Tasks such as colour adjustments that are highly time-consuming on analogue now take seconds

The 3-dimensional hybrid structure that incorporates functional polymers provides high performance for all media types

Make the move from analogue to digital printing – painlessly

Hardware

Recent surveys of the industry suggest the most significant business 'pain points' for label converters are shorter lead times, and finding qualified press operators. So if you're looking for a one-stop shop to solve both these 'growing pains' at once, moving your company seamlessly from conventional to digital label production, opening you up to vast new digital markets and creating small batches of high-quality labels and stickers with a speed and flexibility your customers will talk about, the AccurioLabel 230 is the digital press for you.

You do the printing. Let us do the impositioning.

Software

With its PDF-based workflow and generous feature set, AccurioPro Label Impose is an impressive tool indeed. This software lets operators handle a wide range of pre-press tasks from a single control station, can be married seamlessly with our AccurioLabel 190 hardware, and is the perfect complement to Konica Minolta's label press. The missing piece in your digital label printing puzzle.The only digital label printing software you'll ever need.

Always at your Service

Services

Our experienced, knowledgeable specialist staff will answer any questions you may have, and show you how to operate your product. Our services function for your benefit, within a support system designed to ensure you and your company benefit fully from the solutions. We offer a range of different services, including optimised print services to combine your consulting; hardware and software implementation; workflow management to lower your document spending; and smart security services, to keep your business safe.