There are many exciting evolutions underway in industrial and commercial print but which ones should you focus on in 2025? A Comment by Olaf Lorenz, Head of International Marketing, Konica Minolta Business Solutions Europe

Set to be among the most industry-defining developments are the major advances in Artificial Intelligence (AI), particularly in the realm of Industry 5.0.

Trend 1: Harnessing the power of new technologies for a brighter future

Industry 5.0 emphasizes the symbiotic relationship between humans and technology, recognizing the invaluable contributions of individuals in driving print businesses’ success. By harnessing the power of new technologies such as artificial intelligence (AI) and ‘smart factory’, new opportunities are opening up with digital transformation to optimise companies’ workflows, automate routine tasks, which is also a trend in drupa’s Print Horizons Report. “All printers, regardless of size, region or market, must recognise the seismic shifts in print caused by digitisation1.” This same report also makes it clear2: “All of us are at the beginning of a journey to understand generative AI’s power, reach, and capabilities.”

New technologies can also free up valuable time for employees to focus on more profit-generating activities. Humans will work alongside advanced technology and artificial intelligence-powered robots to enhance workplace processes.

Robots and cobots (a collaborative robot that works with humans in a shared workspace) are all part of our vision towards igniting possibilities and digital transformation in the print room of the future. Empowering printing companies to embrace this future will be open workflow systems that foster creativity and nurture a workforce equipped for success in the digital age. This will help navigate the complexities of digital transformation and unlock the full potential of Industry 5.0.

Trend 2: Greater automation is an essential driver forward for customers

It is also among the reasons why greater automation and innovative end-to-end ecosystems will continue to be high on everyone’s agenda in 2025. These are essential drivers for customers, as well as brands and suppliers. The interest in the ‘smart factory’ technology evolution Konica Minolta demonstrated with MGI (MGI Digital Printing Systems) at drupa 2024 affirms this. Companies both large and small were interested in increased connectivity. They wanted to see how separate processes such as foiling, varnishing, printing, folding, and drying can be combined into one fully integrated production line. MGI’s AlphaJet showcased the benefits of a complete single-pass factory.

Framing this are labor shortages, something explored here in this blog. Following on from last year’s discussion surrounding the challenges of finding, and retaining, skilled employees, automation will become increasingly integrated into the production process. Young people entering the workforce regard digital print machines as more hi-tech than analog. This is a view backed by Smithers3, which adds that digital print offers “greater opportunities for career development and job satisfaction”. This helps with staff retention and attracting new employees.

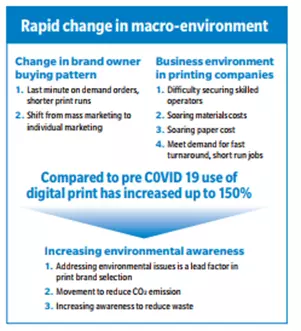

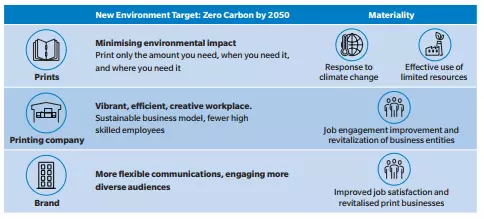

Driving change too, is the unstoppable shift from analog printing to digital printing. In part due to its ability to minimise the environmental impact of printing4. So high-value-added printed materials are used efficiently, and the environmental impact of those materials, which pose the challenges of mass production and disposal, is greatly reduced. Experts are also predicting growth, particularly for digital inkjet, as litho markets continue to shrink overall. Smithers5 states: “Digital can do things that are useful to publishers and marketeers which analogue print cannot accomplish, such as variable data; item versioning; unique codes and personalisation with links to the virtual world.”

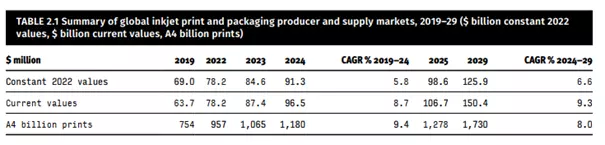

Trend 3: Inkjet and toner markets will continue to increase

Trend 4: Digital embellishment is the next big gamechanger in printing

Trend 5: A global commitment to minimize environmental impact

Trend 6: Cloud hosted digital workflows

In future, all processes will be more highly connected in the cloud with digital workflows. Konica Minolta’s own research13 report says that the pace of digitization along with pressures such as tougher regulatory requirements are forcing a reappraisal of the opportunities afforded by cloud solutions, although SMEs have been slower to adopt than large companies. However, it confirms14: “the adoption of cloud-based solutions by businesses has accelerated as the benefits of more predictable costs, improved security and resilience, and enhance mobility have allowed organisations to become much more agile and efficient.”

Digital transformation will save on IT management, improve security, and reduce print expenses. Eliminating manual processes and automating production steps on the one hand keeps away frustration and worries for organisations. On the other hand, it helps cut material and waste. Konica Minolta’s Ecovision strategy, focuses on ways to responsibly save the resources of our planet.

A commitment to collaboration

Addressing the many operational, environmental and social, political and financial challenges businesses face in 2025 is made easier with collaborative approach. Working together with key partners can help define clear steps and deliver improvements that positively shape healthy growth.

With Konica Minolta’s strong commitments and aspirations to build a lasting legacy, there will be another reason to celebrate in 2025 – its 20th anniversary in commercial print. During those 20 years of innovation, customer needs have provided a catalyst that has inspired passion and commitment. It has helped with the creation of meaningful one-on-one connections and forging an ever-more exciting future.

1 Drupa Print Horizons Report, Executive Summary, Page 1

2 Drupa Print Horizons Report, Executive The Impact of Artificial Intelligence, Page 7

3 Smithers: “The Future of Inkjet Printing to 2029, Key Drivers and Trends, Page 29”

4 Konica Minolta: “Energy & Resource Saving with the AccurioJet KM-1e, Initiatives in the Market”, Page 5

5 Smithers: “The Future of Inkjet Printing to 2029, Key Drivers and Trends”, Page 21

6 Smithers: “The Future of Global Print Equipment Markets to 2028, Executive Summary, Page xxiii

7 Smithers: “The Future of Inkjet Printing to 2029, Key Drivers and Trends”, Page 25”

8 Smithers: “The Future of Inkjet Printing to 2029, The Topline”, Page 7

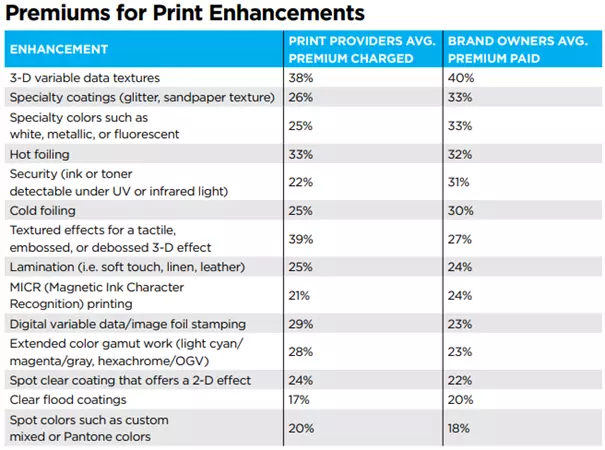

9 NAPCO Research, Adding Value to Digital Printing, Premiums Charged and Paid for Enhancement, Page 18

10 NAPCO Research, Adding Value to Digital Printing, Premiums Charged and Paid for Enhancement, Table on Page 18

11 Konica Minolta: “Energy & Resource Saving with the AccurioJet KM-1e”, Initiatives in the Market, Page 5

12 Konica Minolta: “Energy & Resource Saving with the AccurioJet KM-1e”, Initiatives in the Market, Page 5

13 Konica Minolta: “From a Hesitant Leap of Faith to a Confident Step Forward, Cloud Service Use by SME”, Page 5

14 Konica Minolta: “From a Hesitant Leap of Faith to a Confident Step Forward, Cloud Service Use by SME”, Page 2